Batmobile

Seasoned Member

Hey fellow XLR commune,

I was writing about this in reply to another thread, however, due to age, figured I'll add and write it separately.

Had a problem with the roof hydraulic pump 2/17/22. Due to my own inconsideration, by continue to hold pressing the roof switch for more than necessary while it was stuck in sequence.

My Folding Top sequence had always been to let go of the button on the last step, and then hold it again for the sequence to complete. The last step where the full trunk lid goes down, and in reverse when the lid is going up.

I figured one of the sensors (potentiometers) is out of spec and thus why I need to let go, then hold the button again for the sequence to come to an end.

Not yesterday. While I was holding the button through the sequence as usual, the top stopped where it usually does - but I didn't take my finger off the button - I kept holding the button for about 15 seconds, when it didn't go anywhere, I let go of the button then press it again and the sequence went just fine.

I go on my marry ride, reach the destination and put the top up, (not holding on the button this time) all goes fine.

Problem starts when I get back into the car 20 minutes later, I smell a strong burning odor of plastic coming from the trunk are where the hydraulic pump and control modules are. After a quick visual inspection, I see no leakage or damaged wires/connectors. Get in the car, try to operate the FT and I get an error on the dash "Top too cold to move". I hope for the best and wish a morning start would be back to normal. Not the case.

I checked DTC, and found "B3670" Pump Motor Temperature Sensor Circuit.

Which right away confirmed the smelling burnt plastic odor was coming from the bottom of the hydraulic pump, and meant the thermistor was in question.

ccclarke, the legend, goes over the thermistor and its functionality. Basically it checks the pump motor temp and makes sure its' within spec every 300ms to ensure safe and proper operation.

However, GM pulled a short one here, you'll need the full new pump for $1,500. The thermistor is housed within the motor unit which is covered by the plastic black tube. GM didn't offer the motor unit separately.

Next to the dealer, came TH, or "Top Hydraulics" according to many other XLR owners' feedback had a fantastic experience. Klaus is on another level.

They offer a hydraulic pump rebuild for $800, which is not bad given the dealer option.

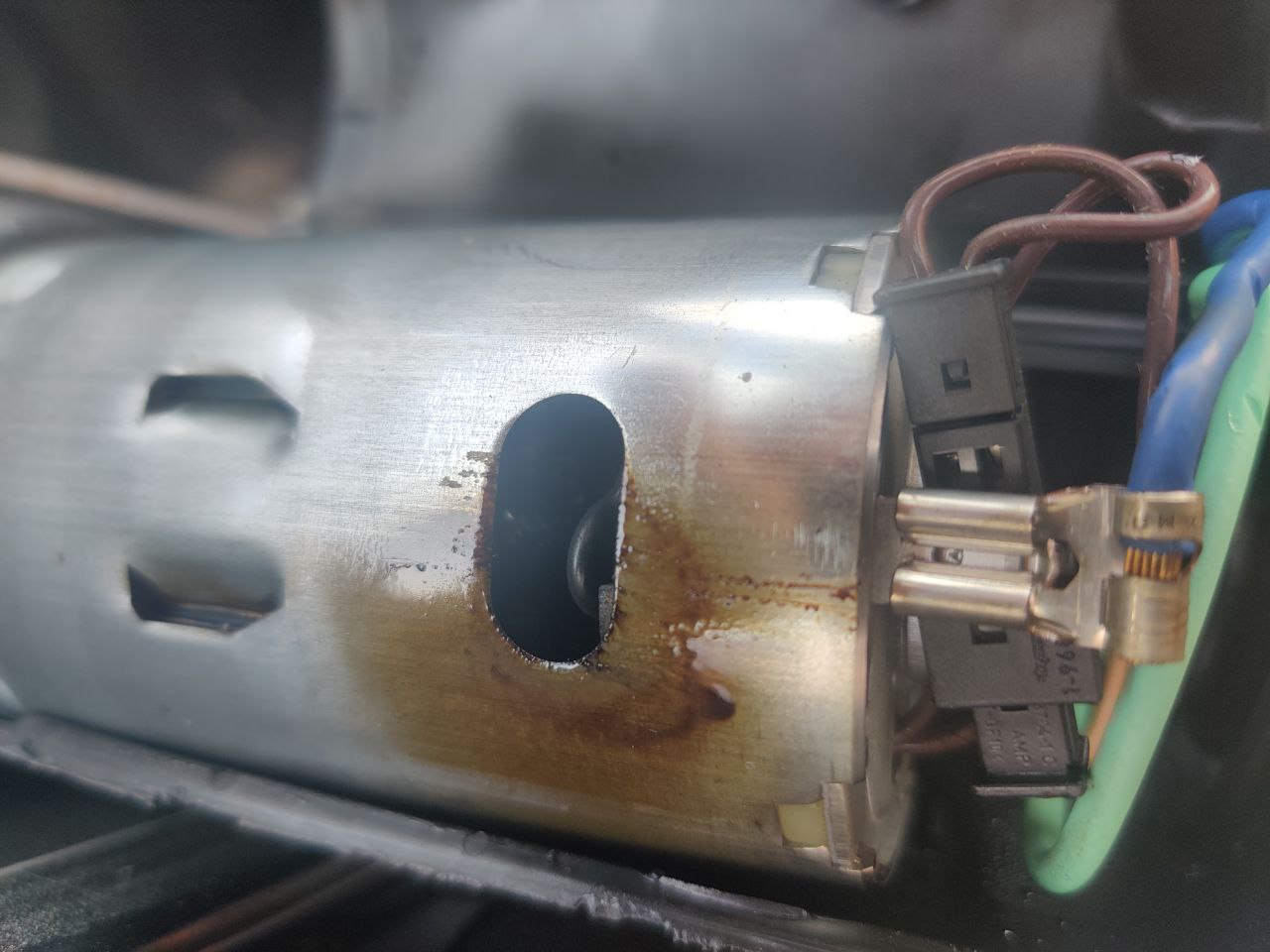

For my problem, it seems that I only need the pump motor unit, as my top worked ok before that melted. I took it apart today 2/18/22. Confirmed the smell came from the motor unit, and can barely see melted electronic parts inside.

For this, I found a cheaper option, which is for a motor pump replacement only.

I came by this site, and will most likely give them a try.

roofmotors.co.uk

roofmotors.co.uk

Has anybody had any experience with the company previously? Or will I have to try it out

Cheers and thanks.

O

I was writing about this in reply to another thread, however, due to age, figured I'll add and write it separately.

Had a problem with the roof hydraulic pump 2/17/22. Due to my own inconsideration, by continue to hold pressing the roof switch for more than necessary while it was stuck in sequence.

My Folding Top sequence had always been to let go of the button on the last step, and then hold it again for the sequence to complete. The last step where the full trunk lid goes down, and in reverse when the lid is going up.

I figured one of the sensors (potentiometers) is out of spec and thus why I need to let go, then hold the button again for the sequence to come to an end.

Not yesterday. While I was holding the button through the sequence as usual, the top stopped where it usually does - but I didn't take my finger off the button - I kept holding the button for about 15 seconds, when it didn't go anywhere, I let go of the button then press it again and the sequence went just fine.

I go on my marry ride, reach the destination and put the top up, (not holding on the button this time) all goes fine.

Problem starts when I get back into the car 20 minutes later, I smell a strong burning odor of plastic coming from the trunk are where the hydraulic pump and control modules are. After a quick visual inspection, I see no leakage or damaged wires/connectors. Get in the car, try to operate the FT and I get an error on the dash "Top too cold to move". I hope for the best and wish a morning start would be back to normal. Not the case.

I checked DTC, and found "B3670" Pump Motor Temperature Sensor Circuit.

Which right away confirmed the smelling burnt plastic odor was coming from the bottom of the hydraulic pump, and meant the thermistor was in question.

ccclarke, the legend, goes over the thermistor and its functionality. Basically it checks the pump motor temp and makes sure its' within spec every 300ms to ensure safe and proper operation.

However, GM pulled a short one here, you'll need the full new pump for $1,500. The thermistor is housed within the motor unit which is covered by the plastic black tube. GM didn't offer the motor unit separately.

Next to the dealer, came TH, or "Top Hydraulics" according to many other XLR owners' feedback had a fantastic experience. Klaus is on another level.

They offer a hydraulic pump rebuild for $800, which is not bad given the dealer option.

For my problem, it seems that I only need the pump motor unit, as my top worked ok before that melted. I took it apart today 2/18/22. Confirmed the smell came from the motor unit, and can barely see melted electronic parts inside.

For this, I found a cheaper option, which is for a motor pump replacement only.

I came by this site, and will most likely give them a try.

Cadillac XLR Roadster Convertible Roof Motor Unit Only 2003-2009 (88958028)

Cadillac XLR Roadster Convertible Roof Motor Unit Only 2003-2009 (88958028) Roof motor failed? We supply reconditioned units with a 12 month warranty

roofmotors.co.uk

roofmotors.co.uk

Has anybody had any experience with the company previously? Or will I have to try it out

Cheers and thanks.

O